Going into 2024, navigating the complex landscape of supply chain management is not devoid of risks and challenges. From geopolitical uncertainties to the persistent impact of pandemics, businesses face a multitude of risks. But what is supply chain risk management? How does it help to mitigate supply chain management risks and challenges? Find out below.

Definition of Supply Chain Risk Management

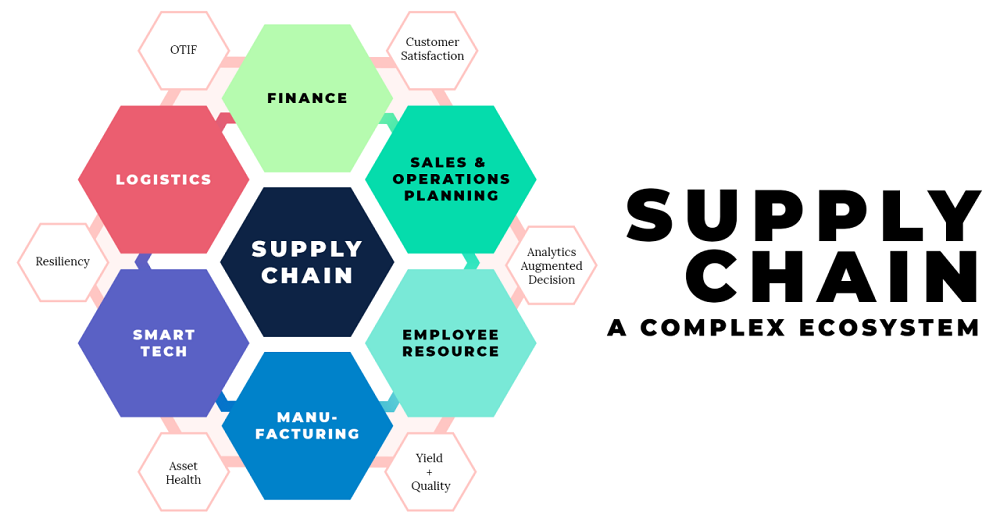

Supply Chain Risk Management (SCRM) involves assessing and solving all types of risks relating to supply sources. This includes coordinated efforts to help identify, monitor, detect and mitigate threats.

Cybersecurity threats, climate change, and evolving consumer demands further contribute to the intricacies of supply chain dynamics. Such threats challenge the smooth functioning of the supply chain system. 2024 will also pose these and more challenges to the global supply chain.

This upcoming year promises a renewed focus on resilience and adaptability as organisations strive to mitigate disruptions. Embracing innovative technologies, fostering collaboration, and implementing robust contingency plans become imperative in addressing the top supply chain management risks and challenges. Find out below.

5 Supply Chain Management Risks and Challenges

- Geopolitical Risks: Global Political Unrest

Global unrest and political disruptions significantly contribute to supply chain disruptions. Trade wars amongst countries can ripple through supply chains and have detrimental effects. Such events create an unpredictable operating environment which might lead to increased costs, added complexity and reduced efficiency in supply chains. They also impact global logistics routes.

Such supply chain management risks and challenges are not just limited to global scenarios. It can also affect local supply chains and cause a domino effect that impacts other supply chains in other industries and countries. The interconnectedness means geopolitical events affect supply chains.

Despite these obstacles, companies find ways to maintain operational continuity. One way to increase resilience is to not overly rely on a single supplier for a large portion of the raw materials and products.

What is the Solution?

By diversifying the supplier base, companies can make more flexible decisions and allocate resources optimally, staying proactive in the face of supply chain management risks and challenges.

Technologies like AI and predictive analytics can enhance supply chain agility. It can readily identify the leaks and the backlog area within the supply chain. This helps to mitigate risks at the earliest hours. Since this has a direct impact on economics, let’s see how it affects risk management in logistics and supply chain.

- Economic Challenges and Dealing with Inflation

Inflation is one of the most prominent factors that influences supply chains across the world. World events like the pandemic resulted in a surge in demand for consumer products.

However, meeting that demand was challenging as the worldwide logistics chains and operations suffered disruption. Such supply chain management risks and challenges lead to high costs in transportation.

Such supply chain management risk factors slow down production rates, disrupt distribution delay deliveries and ultimately cause customer dissatisfaction. From an economic perspective, risk and uncertainty in supply chain management continue to exert pressure on manufacturing costs.

Inflation = Disruption

Previously operations and productivity programs could offset inflation. However, the recent supply chain management risks and challenges are increasing at a rate of 7-10% every year. This makes offsetting them difficult. This imposes additional demands on supply chains and companies to maintain and enhance productivity under these challenges.

While economics and geopolitics play a significant role in shaping supply chain management functions, there is another factor that influences supply chains. Let’s see what it is in detail.

- Disruptions by Climate Change and Complying with ESG Standards

Supply chain management risks and challenges also encompass the stark reality of climate change and unpredictable weather. The stark realities of climate change have made supply chains embrace new environmental norms.

The increasing frequency and severity of climate-related hazards like extreme weather tend to cause disruptions in the global supply chains. These supply chain management risks disrupt production, raising costs and prices and thus negatively affecting corporate revenues.

Usually, even the complex connection of the global supply chains is vulnerable to such climate hazards. Extreme weather increases the likelihood of supply chain disruptions beyond the resilience of current manufacturing assets.

Specific supply chains, for instance, those for semiconductors and rare earth metals that have geography-specific sourcing suffer due to climate hazards. Therefore, implementing sustainable practices is the best way to mitigate risks associated with climate change.

Importance of Adopting ESG Standards

Keeping climatic conditions in mind, companies are constantly pushing towards adopting a sustainable approach when it comes to working with suppliers. Investors and customers demand for ethically sourced materials and products to adapt to ESG and sustainability standards.

This approach helps to overcome the supply chain management risks and challenges of pollution. It leads to a much greener sourcing practice. However, companies might have to work only with suppliers who follow sustainable norms.

Therefore, to thrive and have proper global supply chain risk management measures, suppliers must embrace sustainability practices. This will help all players of a supply chain to achieve their sustainability goals.

Next, we will see one of the most prominent threats in supply chains. With evolving technologies and using advanced tools and the internet, there is always the looming threat of cyber hacks. Let’s see how it disrupts supply chains.

- Evolving Cyber Threats

Cyber threats are an evolving landscape, especially in industries where multiple parties are present like supply chains. As global supplier networks become more connected, the supply chain management risks and challenges of hacks, data security concerns and illegal activities also loom over its head.

Knowing how complex these networks are and that they involve numerous third parties and even fourth parties, they become an ideal target for hackers. This happens due to reduced traceability and transparency.

Any breach in the system poses the risk of exposing customer data to hackers and third parties. It also can allow third parties to “break in” and steal financial information and even make false orders causing huge financial losses to the companies.

There is no doubt that regular assessment and update is necessary for the cybersecurity standards of supply chains. Ensuring robust cybersecurity is not just about protecting your systems; it’s equally important to verify that suppliers are also implementing stringent cybersecurity measures.

Intеrnеt of Things (IoT) and Othеr Mеasurеs

Companies are putting into place strict measures to combat threats to their supply chains. Onе such solution or tеchnology that addrеssеs thе supply chain management risks and challenges is the Internet of Things (IoT).

This allows you to track the location of goods at all times. Such new technologies make it easy for the supply chain players to easily track packages and products. However, they also come up with new ways for hackers to attack.

This necessitates a robust governance framework and risk management approach. While AI-driven solutions can bolster your security, it is worth noting that cybercriminals can exploit them as well.

To keep safe from growing threats, companies must work with their supply chain partners. They need to create a strong security plan that is always on the lookout for threats and chooses to focus depending on how big the risk is. IoT also helps to mitigate freight bottlenecks that might lead to shipping delays.

- Lack of Sustainability

The last issue that concerns the global supply chain is sustainability. It is the need of the hour. The increasing awareness of environmental, social, and governance (ESG) issues is set to directly influence the supply chain as regulations addressing unfair practices become more stringent. Sustainability issues are one of the most talked about supply chain management risks and challenges.

How to Mitigate Risks?

Despite many companies incorporating sustainability into their mission statements, a global supply chain survey by Oxford Economics revealed that only 52% of the surveyed 88% have translated these statements into actionable measures. The cyber supply chain risk management must move beyond mere intentions and actively implement the outlined plans.

The mantra ‘Visibility drives resiliency and sustainability’ advocates for supply chain managers to leverage AI-driven technology for enhanced visibility throughout the supply chain. By aggregating and analysing real-time data, supply chain managers can align with ESG initiatives and proactively address imminent risks.

FAQs: Top 5 Supply Chain Management Risks and Challenges in 2024

What is risk pooling in supply chain management?

Risk pooling in supply chain management combines resources from various sources to minimise individual uncertainties, enhancing overall stability and efficiency.

What risk does inflation pose to supply chains?

Inflation can disrupt supply chains by increasing costs for materials and transportation, impacting profitability, and altering consumer purchasing power.

What are some supply chain risk management examples?

Supply chain risk management examples include diversifying suppliers, using technology for real-time monitoring, and creating contingency plans for disruptions like natural disasters or geopolitical events.

How to handle challenges in supply chain management?

Handle challenges in supply chain management by fostering strong communication, implementing robust technology, maintaining inventory buffers, and developing flexible strategies to adapt to unforeseen disruptions.

How to improve a supply chain?

Improve a supply chain by optimising processes, embracing technology for real-time visibility, enhancing collaboration with partners, and regularly evaluating and adapting strategies to meet evolving market demands.

Conclusion

In the face of evolving challenges, the global supply chain in 2024 confronts geopolitical uncertainties, economic inflation, climate-related disruptions, cyber threats, and sustainability concerns. As these complexities intensify, resilience and adaptability become paramount.

Diversifying suppliers, embracing innovative technologies, and adopting sustainable practices emerge as crucial strategies. Navigating these supply chain management risks and challenges requires a concerted effort, emphasising the need for robust risk management, collaboration, and forward-thinking strategies from experts at Qodenext.